Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 22, 2026

GC-MS Flavor Analysis Lab

In the rapidly evolving world of electronic nicotine delivery systems (ENDS), the “flavor” is more than just a sensory experience; it is a complex chemical matrix. For a manufacturer of specialized flavorings, the transition from a laboratory formulation to a commercial product involves a rigorous gauntlet of quality control (QC). At the heart of this process lies one of the most powerful tools in modern science: Mass Spectrometry (MS).

While sensory testing (smelling and tasting) is vital for profile development, it cannot detect trace levels of contaminants, nor can it provide a molecular breakdown of a complex mixture. Mass Spectrometry acts as our “molecular eyes,” allowing us to see exactly what is inside every batch before it leaves our facility. This article provides a technically detailed exploration of how we use Mass Spectrometry to verify flavor purity, the physics behind the technology, and why this level of scrutiny is non-negotiable for “vape-grade” concentrates.

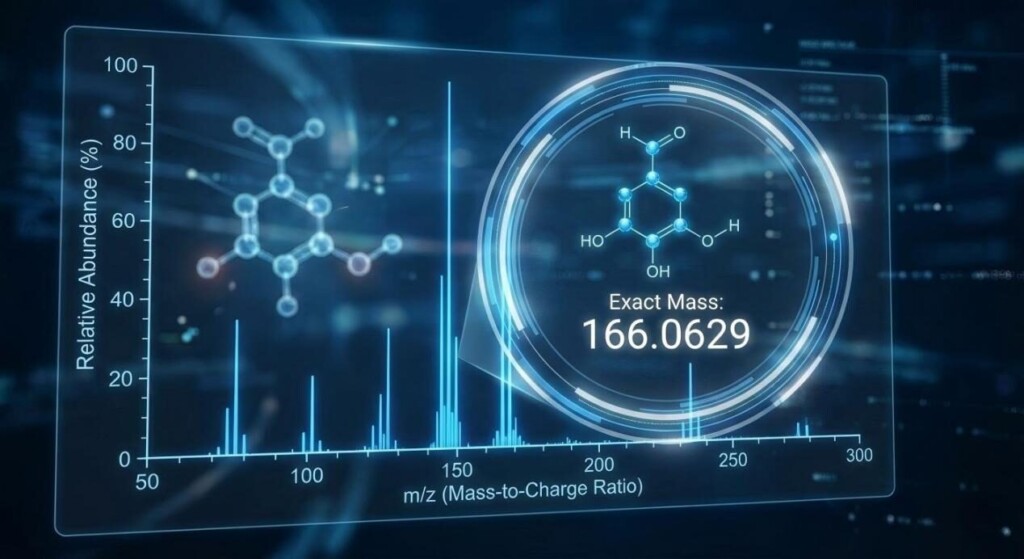

At its most fundamental level, mass spectrometry is an analytical technique that measures the mass-to-charge ratio (m/z) of ions. Unlike a traditional scale that measures weight, a mass spectrometer measures the characteristics of individual molecules by converting them into a gas phase and then into electrically charged particles (ions).

As defined by the International Union of Pure and Applied Chemistry (IUPAC), a mass spectrometer is “an instrument that measures the mass-to-charge ratio and relative abundances of ions.” This definition highlights the two critical data points we receive: what a molecule is (mass) and how much of it is there (abundance).

CITATION 1: For standardized terminology and the formal definition of analytical techniques, professionals refer to the IUPAC Compendium of Chemical Terminology (the “Gold Book”).

Source: IUPAC Gold Book – mass spectrometer. Available at: https://goldbook.iupac.org/terms/view/M03733

For flavorings, this allows us to identify the specific esters, aldehydes, and ketones that create a “Strawberry” or “Caramel” profile, while simultaneously scanning for any molecules that shouldn’t be there—such as residual solvents, heavy metals, or prohibited diketones.

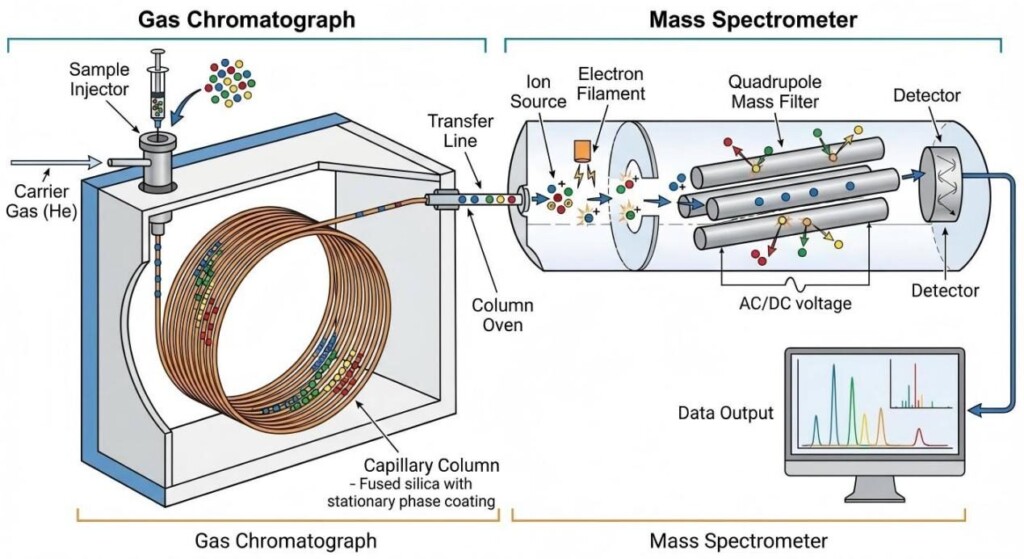

The journey of a flavor sample through a mass spectrometer involves three distinct stages: Ionization, Acceleration/Separation, and Detection. To understand how we verify purity, we must look at the technical mechanics of each stage.

A neutral molecule cannot be manipulated by the magnetic or electric fields inside the machine. Therefore, the first step is to turn the liquid flavor concentrate into a stream of ions.

In flavor analysis, the most common method is Electron Ionization (EI). Here, the sample is bombarded with a beam of high-energy electrons (typically at 70 eV). When an electron strikes a flavor molecule, it knocks an electron off the molecule, creating a positively charged radical cation (M+.).

Because 70 eV is much higher than the energy required to simply ionize the molecule, it causes the molecule to shatter into predictable fragments. These fragments are like “shards” of a glass vase; by looking at the pieces, we can reconstruct the original structure.

Once ionized, the particles are accelerated into the Mass Analyzer. This is the “brain” of the machine. The most common type used in flavor QC is the Quadrupole.

A quadrupole consists of four parallel metal rods. By applying specific radiofrequency (RF) and direct current (DC) voltages to these rods, we can create a “filter” that only allows ions of a specific m/z to pass through at any given microsecond. All other ions collide with the rods and are neutralized. By rapidly “sweeping” through different voltages, the machine “counts” ions of every possible mass in the sample.

Finally, the ions hit a detector (often an Electron Multiplier). Each time an ion strikes the detector, it creates a small electrical pulse. The intensity of these pulses tells us the concentration of that specific molecule in the flavor batch.

While MS is powerful, it has a limitation: it struggles to analyze 50 different chemicals at the exact same time. If we injected a raw e-liquid concentrate directly into an MS, the resulting data would be a chaotic mess of overlapping signals.

To solve this, we couple it with a Gas Chromatograph (GC). This hyphenated technique, GC-MS, is the industry’s gold standard for flavor purity.

GC-MS Internal Workflow Diagram

By the time the sample reaches the Mass Spectrometer, the complex flavor has been separated into its individual components. The GC provides the time (when it came out), and the MS provides the identity (what it is).

How do we know that the peak at 12.5 minutes is actually Isoamyl Acetate (the molecule that smells like banana) and not an unwanted impurity? We use Spectral Libraries.

When a molecule fragments in the Ion Source, it creates a unique pattern of peaks called a Mass Spectrum. This pattern is as unique as a human fingerprint. We compare the spectrum generated by our sample against massive databases maintained by organizations like the National Institute of Standards and Technology (NIST).

CITATION 2: The NIST Mass Spectrometry Data Center develops and maintains the world’s most widely used mass spectral libraries, containing hundreds of thousands of evaluated spectra for compound identification.

Source: NIST Mass Spectrometry Data Center. Available at: https://chemdata.nist.gov/

If we find a peak that does not match our known “Master Formula” or the NIST library, our chemists immediately flag the batch. This allows us to identify “unknown unknowns”—contaminants that might have been introduced via raw material suppliers or during the manufacturing process.

For e-liquid flavorings, “food grade” (GRAS – Generally Recognized as Safe) is a baseline, but it is not the final destination. Food-grade flavors are designed for ingestion, where the stomach’s acid and the liver’s metabolism provide a layer of protection. When those same chemicals are aerosolized and inhaled, the safety profile changes entirely.

Mass Spectrometry allows us to verify the absence or strict limitation of several “High-Priority” compounds:

Compounds like Diacetyl and Acetyl Propionyl are famous for creating “buttery” or “creamy” notes. However, they have been linked to respiratory issues when inhaled in high concentrations. While many manufacturers claim to be “Diacetyl-Free,” we use GC-MS to prove it. Our systems can detect these compounds at parts-per-million (ppm) or even parts-per-billion (ppb) levels, far beyond the capability of basic lab tests.

During the extraction of natural flavors or the synthesis of aromatics, small amounts of aldehydes like Formaldehyde or Acetaldehyde can sometimes be present as byproducts. High-resolution mass spectrometry ensures these are below detectable safety limits before the product is ever bottled.

For natural extracts (such as tobacco or fruit-derived essences), there is a risk of soil contaminants. Using ICP-MS (Inductively Coupled Plasma Mass Spectrometry), we can detect trace heavy metals like Lead, Arsenic, and Cadmium to ensure they meet stringent international safety standards.

CITATION 3: The U.S. Food and Drug Administration (FDA) provides guidance on the “Listing of Ingredients in Tobacco Products,” emphasizing the need for accurate chemical reporting and the monitoring of potentially harmful constituents.

Source: FDA – Listing of Ingredients in Tobacco Products (Revised). Available at: https://www.fda.gov/media/101162/download

While GC-MS is excellent for volatile aroma compounds, some flavor components are “heavy” or heat-sensitive and won’t turn into a gas easily. For these, we use Liquid Chromatography-Mass Spectrometry (LC-MS).

In LC-MS, the sample remains in a liquid solvent. This is particularly useful for analyzing:

Furthermore, we utilize High-Resolution Accurate Mass (HRAM) spectrometry. Standard machines might tell us a molecule has a mass of 150. HRAM machines can tell us the mass is 150.0682. This level of precision allows us to determine the exact elemental formula (C8H10O3, for example), leaving zero room for ambiguity.

Mass Spectrum Data Visualization

How does this technical science translate into the bottle of flavor concentrate you receive? We follow a “Three-Gate” verification process.

Every raw chemical (the “ingredients” of our flavors) undergoes an initial GC-MS scan upon arrival. If a supplier sends us an “99% pure” ester that shows 2% unknown impurities, the entire shipment is rejected. We only build our flavors on a foundation of validated purity.

During the blending process, we take samples to ensure that the chemical reactions (if any) are proceeding as expected. This ensures that the “Chemical Fingerprint” of the batch matches our proprietary Master Profile.

Before shipping, a final GC-MS analysis is performed. This data is used to generate the Certificate of Analysis (COA). When you buy from us, the COA isn’t just a piece of paper; it is a summary of the mass spectral data that proves your batch is pure, consistent, and safe for its intended use.

CITATION 4: A study published in MDPI Toxics emphasizes that the development of “Flavor Ingredient Wheels” and the use of GC-MS are essential for linking specific additives to e-liquid safety and regulatory compliance.

Source: Development of a Flavor Ingredient Wheel Linking E-Liquid Additives to the Labeled Flavor of Vaping Products – MDPI. Available at: https://www.mdpi.com/2305-6304/12/5/372

As we look forward, the integration of Artificial Intelligence (AI) with Mass Spectrometry is the next frontier. We are currently training algorithms to recognize subtle “drifts” in flavor profiles that even the most experienced chemist might miss. By analyzing thousands of historical mass spectra, our AI can predict how a flavor might interact with different PG/VG ratios or how it might age over time.

This ensures that our clients don’t just get a product that is pure today, but one that remains stable and high-performing throughout its shelf life.

The e-liquid industry is under more scrutiny than ever before. Consumers demand transparency, and regulators demand data. As a manufacturer, we believe that the only way to meet these demands is through a “Science-First” approach.

Mass Spectrometry is not just an expensive piece of lab equipment; it is our commitment to you. It is the guarantee that every drop of flavor concentrate we ship has been scrutinized down to the molecular level. Whether you are a small boutique brand or a large-scale manufacturer, our analytical rigor ensures that your final product stands out for its quality, its flavor, and—most importantly—its safety.

Quality-Assured Flavor Concentrates

Are you looking for a flavoring partner that prioritizes analytical precision? Whether you need a technical exchange regarding specific compound limits or you’re ready to test our “vape-grade” concentrates, our team is ready to help.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy