Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 21, 2026

Pensky-Martens Flash Point Testing

For manufacturers of e-liquids, the pursuit of the perfect flavor profile—that precise balance of strawberry and cream, or tobacco and caramel—is paramount. As a flavor concentrate manufacturer, our role is to supply the complex, highly concentrated building blocks that make those final products possible. However, the very chemistry that allows these concentrates to carry intense aromas and combine seamlessly with vegetable glycerin (VG) and propylene glycol (PG) often introduces a significant logistical challenge: flammability.

The logistics of the vaping industry are under constant scrutiny. Moving concentrated flavorings across borders and oceans isn’t just about speed; it’s about rigid adherence to international safety standards. The central metric governing the safety of shipping these volatile mixtures is the Flash Point.

Ignoring flash point data isn’t merely a paperwork oversight; it is a direct violation of international law, a severe safety hazard for logistics personnel, and a guaranteed way to have critical shipments seized by customs or rejected by carriers.

This article serves as an authoritative, deeply technical guide for e-liquid manufacturers, procurement managers, and logistics coordinators. We will dissect the science of flash point, explore the labyrinth of international regulatory bodies (IATA, IMDG, DOT), explain the crucial classification system for “Class 3 Flammable Liquids,” and provide actionable strategies for compliant, efficient shipping of flavor concentrates. Understanding these dynamics is essential for maintaining an uninterrupted supply chain in the competitive e-cigarette market.

Before diving into regulations, we must establish a precise scientific definition of flash point, distinct from other thermal properties like boiling point or auto-ignition temperature.

The flash point of a volatile material is the lowest temperature at which its vapors will ignite if given an ignition source.

It is crucial to understand that the liquid itself does not burn. Flammability is driven by the vapors the liquid gives off. As the temperature of a flavor concentrate rises, the kinetic energy of its molecules increases, causing more molecules to escape the liquid phase and enter the vapor phase immediately above the surface.

When the concentration of this vapor in the air reaches a specific threshold—known as the Lower Flammable Limit (LFL) or Lower Explosive Limit (LEL)—the mixture becomes ignitable. The temperature at which this precise vapor concentration is achieved is the flash point. If an ignition source (a spark, an open flame, static electricity) is introduced at or above this temperature, the vapor will “flash,” or ignite momentarily.

It is vital not to confuse flash point with related concepts:

For shipping regulations, the flash point is the definitive metric because it represents the minimum threshold for a fire hazard during transport conditions.

Flavor concentrates for e-liquids are rarely single chemical entities. They are complex solutions. The active flavor compounds (esters, aldehydes, ketones, pyrazines) are often highly potent and must be dissolved in a carrier solvent to be usable.

While Propylene Glycol (PG) is a common carrier and has a relatively high flash point (~104°C / 219°F), making it generally non-regulated for flammability, many potent flavor extracts require stronger solvents.

The primary culprit for low flash points in flavor concentrates is Ethanol (Ethyl Alcohol). Ethanol is an excellent solvent for extracting natural flavors and carrying volatile aromatics. However, pure ethanol has a flash point of approximately 13°C (55°F). Even when diluted in a concentrate, a significant percentage of ethanol can easily drag the entire mixture’s flash point down below regulatory thresholds.

Other common flavor volatiles, such as Ethyl Acetate (used for fruity/sweet notes), have very low flash points (around -4°C / 25°F) in their pure form. Even small percentages of these highly volatile compounds can significantly impact the overall flammability classification of a concentrate.

How is this temperature determined? Regulatory bodies almost universally require the use of Closed-Cup Test Methods.

In an open-cup test, vapors are allowed to dissipate into the ambient air. In a closed-cup test, the sample is heated in a sealed vessel containing air. This simulates conditions in a sealed shipping container where vapors can accumulate. Because the vapors are contained, closed-cup tests almost always result in a lower (more conservative and safer) flash point reading than open-cup tests.

Standard test methods referenced by international regulations include:

For shipping flavor concentrates, relying on an open-cup value is a critical error that can lead to misclassification and regulatory penalties.

Shipping flammable liquids isn’t governed by a single entity. It is a complex web of international agreements implemented by national authorities and specific transport modes. Understanding this hierarchy is essential for global compliance.

At the apex sits the United Nations (UN). The UN Committee of Experts on the Transport of Dangerous Goods develops the UN Recommendations on the Transport of Dangerous Goods—Model Regulations. This “Orange Book” provides the framework that most nations and modal authorities adopt to ensure consistency.

CITATION 1: For detailed insights into the foundational framework for global dangerous goods transport, refer to the United Nations Economic Commission for Europe (UNECE), which publishes the “UN Recommendations on the Transport of Dangerous Goods – Model Regulations.” Available at: https://unece.org/transport/dangerous-goods

Below the UN framework, specific organizations govern different modes of transport:

A flavor manufacturer must classify their product so that it complies with all regulations it will encounter during its journey. A shipment originating in the US, traveling by truck to an airport, flying to Germany, and trucking to a final destination must simultaneously comply with DOT, IATA, and ADR regulations.

Under the UN system, dangerous goods are divided into nine classes. Flammable liquids fall squarely into Class 3.

If a flavor concentrate has a closed-cup flash point of 60°C (140°F) or below, it is generally considered a Class 3 Flammable Liquid for transport purposes.

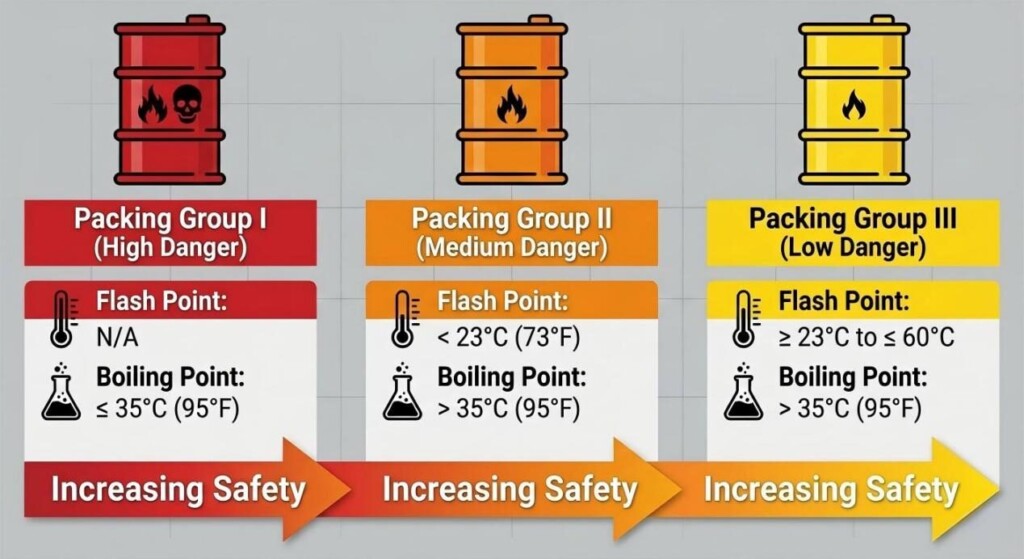

However, simply knowing it’s “Class 3” is insufficient. The degree of danger must be further defined by assigning a Packing Group (PG). The Packing Group determines the type of packaging required, the maximum quantities allowed per package, and the labeling mandates.

Packing Groups are assigned based on a combination of Flash Point and Initial Boiling Point:

Flammable Liquids Packing Groups Infographic

The distinction between PG II and PG III is massive in terms of logistics costs. A flash point of 22°C forces a product into Packing Group II, which significantly lowers the maximum quantity permitted aboard passenger and cargo aircraft compared to a product with a flash point of 24°C (Packing Group III).

For a flavor manufacturer, precise formulation and testing around this 23°C threshold is a critical aspect of product development logistics.

The communication tool for this technical data is the Safety Data Sheet (SDS). As a manufacturer, it is our legal obligation to provide an accurate, globally harmonized SDS for every mixture we create.

For e-liquid manufacturers receiving our goods, the SDS is not just a document to file away; it is the blueprint for compliant shipping of their finished goods (if they remain flammable) and for ensuring workplace safety.

CITATION 2: The requirements for Safety Data Sheets, including the standardized 16-section format and the criteria for classification, are detailed in the “Globally Harmonized System of Classification and Labelling of Chemicals (GHS),” published by the United Nations. Information on GHS implementation can also be found via the Occupational Safety and Health Administration (OSHA) in the US. Source: https://www.osha.gov/dsg/hazcom/ghsguideoct05.pdf

Section 9 (Physical and Chemical Properties) and Section 14 (Transport Information) of the SDS are paramount regarding flash point.

If an SDS is inaccurate—for example, listing a PG II item as PG III due to sloppy testing or reliance on open-cup data—the receiving party who then re-ships that product using the erroneous data inherits the liability for undeclared dangerous goods.

Once a flavor concentrate is identified as Class 3, it cannot be shipped in standard cardboard boxes with generic tape. It requires UN-Specification Packaging.

These packages (boxes, drums, jerricans) have been rigorously tested (drop tests, stack tests, pressure tests) to ensure they can withstand the rigors of transport without leaking, even if subjected to pressure changes in an airplane cargo hold.

UN packaging bears a specific code marked permanently on the exterior, such as: UN 4G/Y1.4/S/23/USA/M1234.

Using a non-UN box for a hazardous shipment is an immediate compliance failure.

The exterior of the package must clearly display:

For the vaping industry, which often deals in smaller bottles of concentrates (e.g., 30ml, 120ml, 500ml), full regulation hazmat shipping can be prohibitively expensive and complex. Fortunately, regulatory bodies provide relief for smaller shipments through “Limited Quantity” (LQ) exceptions.

Shipping under Limited Quantity rules provides significant benefits: it often eliminates the need for UN-specification outer packaging (though sturdy packaging is still required) and, crucially, often removes the requirement for expensive Dangerous Goods Declaration (DGD) paperwork and certain carrier surcharges.

The applicability of LQ depends entirely on the Packing Group:

Limited Quantity Shipping Mark

If you exceed these inner limits—for example, shipping a single 5-liter jug of a PG II concentrate—you cannot use Limited Quantity provisions. You must ship it as fully regulated dangerous goods with full UN packaging and paperwork.

Furthermore, air transport (IATA) has much stricter rules for LQ than road or sea. Some airlines may refuse LQ shipments entirely, or require different labeling (the ‘Y’ limited quantity mark).

CITATION 3: The Pipeline and Hazardous Materials Safety Administration (PHMSA), under the U.S. Department of Transportation, provides detailed guidance on Limited Quantity exceptions within 49 CFR Part 173.150. Information available at: https://www.phmsa.dot.gov/

As a manufacturer of e-liquids buying concentrates, you are part of the chain of responsibility. Here is how you can ensure safety and compliance upon receipt and subsequent handling:

The rules surrounding flash point and shipping aren’t merely bureaucratic hoops; they are written in response to historical disasters. Ignoring them carries severe consequences.

CITATION 4: The National Fire Protection Association (NFPA) is a leading global advocate for fire and electrical safety. Their codes and standards, such as NFPA 30 (Flammable and Combustible Liquids Code), highlight the severe risks and necessary precautions for handling these materials. Source: https://www.nfpa.org/

In the world of flavor concentrate manufacturing, creating a stellar flavor profile is only half the battle. Ensuring that product reaches its destination safely and legally is equally vital.

Flash point is the critical pivot point around which the entire logistics strategy for a flavor concentrate revolves. It dictates the packaging you use, the labels you apply, the carriers you can utilize, and the costs you will incur.

By understanding the science of flash point, respecting the hierarchy of international regulations, and utilizing provisions like Limited Quantity intelligently, manufacturers can navigate the complexities of hazmat shipping. At our company, we view compliance not as a burden, but as an integral part of our quality promise—ensuring that the intense aromas we create inspire e-liquid makers around the world without compromising safety along the journey.

Loading Flammable Liquids for Global Transport

Are you navigating the complexities of formulating or importing flavor concentrates and need technical clarity on flash points and shipping regulations? Do you need access to a library of high-quality flavor concentrates that come with precise, compliant Safety Data Sheets every time?

Contact our technical team today. We can help you select the right flavor profiles that meet both your sensory goals and your logistical requirements. Let’s ensure your supply chain remains safe, compliant, and efficient.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy