E-liquid bottle and sediment display

Introduction:In the pursuit of dense vapor clouds and smooth throat hits, high-Vegetable Glycerin (VG) e-liquids have become a staple for many vapers. However, this preference for VG-heavy formulations introduces a unique and often frustrating challenge for manufacturers and consumers alike: flavor sedimentation. This phenomenon, where flavor compounds separate from the e-liquid and settle at the bottom of the bottle, isn’t just an aesthetic issue; it directly impacts flavor consistency, perceived quality, and the overall vaping experience. A flavor profile meticulously crafted to perfection can become muted, unbalanced, or even unpleasant if its crucial aroma components are sitting as an inert layer at the bottom of the bottle.

Understanding the root causes of flavor sedimentation in high-VG bases requires delving into the intricate chemistry of solubility, density, and intermolecular forces. It’s a battle against the fundamental properties of disparate liquids and solids trying to coexist in a viscous environment. For e-liquid manufacturers striving for product excellence and consumer trust, mastering the prevention and mitigation of sedimentation is paramount to delivering a consistently high-quality product in the thriving high-VG market.

This article delves into the technical intricacies of flavor sedimentation in high-VG e-liquids. We will explore the scientific reasons behind this separation, identify the most vulnerable flavor types, outline strategic formulation and manufacturing practices to prevent it, and how a proactive approach to solving this challenge is essential for ensuring flavor integrity and product consistency in a high-VG world.

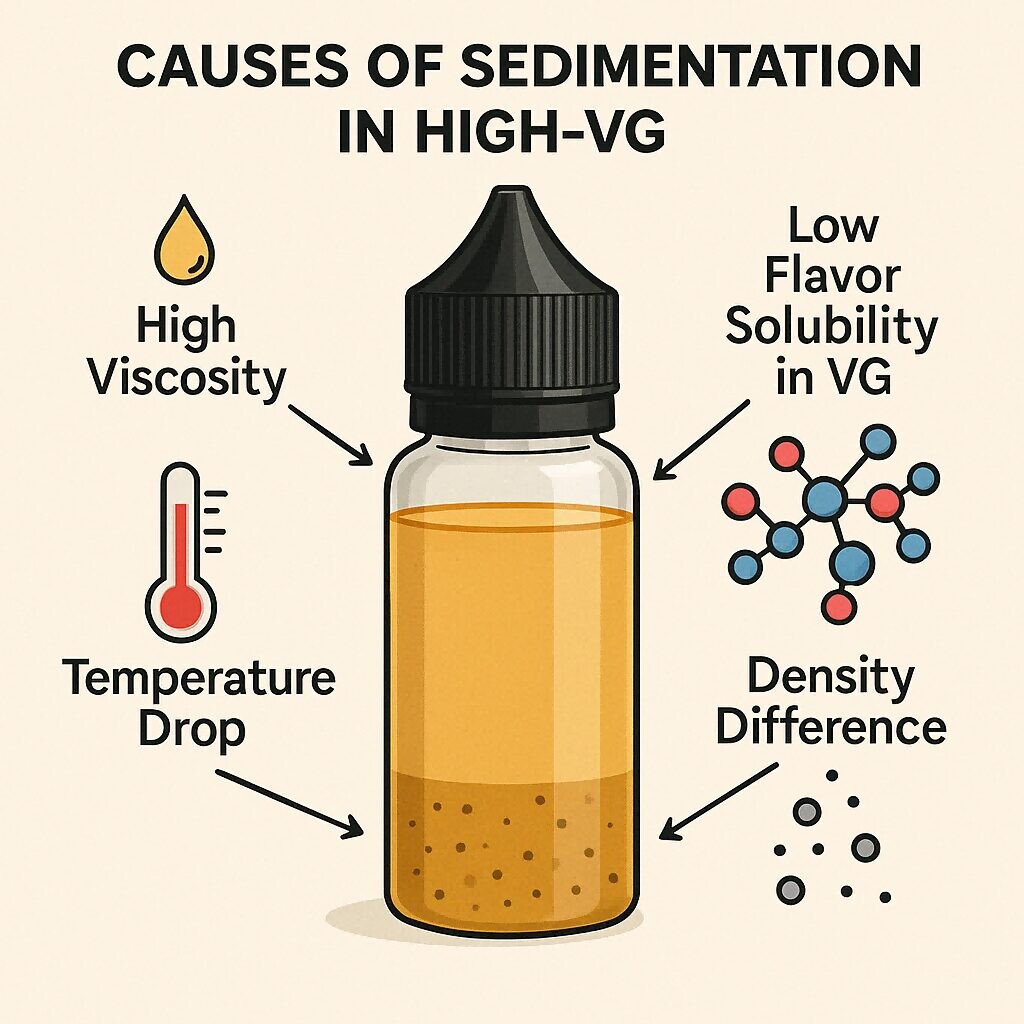

Flavor sedimentation occurs when flavor compounds (or other components) lose their stable dispersion within the e-liquid, aggregate, and settle out of solution. This is particularly prevalent in high-VG bases due to several interconnected factors:

(1)Mechanism:Vegetable Glycerin is significantly more viscous (thicker) than Propylene Glycol (PG). This high viscosity creates a “slower” solvent environment.

(2)Impact:In a highly viscous medium, it’s harder for less soluble flavor compounds to remain suspended or fully dissolve. Once particles begin to aggregate, the high viscosity slows down their re-dispersion, making them more likely to settle and remain settled due to gravity. Think of trying to dissolve sugar in honey versus water – the former takes much longer and the sugar is more likely to settle.

(1)Mechanism:Many aroma chemicals are naturally more soluble in PG (a smaller, more polar molecule) than in VG (a larger, less polar molecule). While flavor concentrates themselves are typically diluted in PG, when these concentrates are added to a high-VG base, the overall solvent environment shifts dramatically towards VG.

(2)Impact:Flavor compounds that are highly soluble in PG but poorly soluble in VG will “fall out” of solution (precipitate) as the VG concentration increases. This can lead to visible particles or a distinct layer at the bottom of the bottle.

(3)Common Culprits:Certain natural extracts (e.g., vanilla absolute, some fruit extracts), high molecular weight flavorants (e.g., some creamy, caramel, or bakery notes), certain sweeteners (e.g., sucralose at high concentrations), and some cooling agents.

(1)Mechanism:If the aggregated flavor particles or a separated flavor oil layer have a significantly different density than the surrounding high-VG e-liquid, gravity will pull the denser component downwards, leading to sedimentation or layering.

(2)Impact:Creates visible separation, where a clear top layer sits above a cloudy or particulate bottom layer.

(1)Mechanism:Solubility decreases with decreasing temperature for many compounds. If an e-liquid is mixed and stable at room temperature, but then exposed to colder temperatures (e.g., during winter shipping, refrigerated storage, or simply a cold room), poorly soluble compounds can “cold crash” out of solution.

(2)Impact:Leads to sudden and often irreversible sedimentation or crystallization. Once precipitated, it can be very difficult to redissolve these compounds without heating or intense agitation, especially in a high-VG base.

(1)Mechanism:The strength of attraction between flavor molecules and PG/VG molecules versus the attraction between flavor molecules themselves determines solubility. In high-VG bases, the attractive forces between poorly soluble flavor molecules can become stronger than their attraction to VG, causing them to clump together.

(2)Impact:Promotes aggregation and subsequent settling.

Flavor sedimentation manifests visibly and profoundly impacts the vaping experience.

Overview of causes of high VG sediment

Successfully combating flavor sedimentation in high-VG bases requires a proactive, scientific approach from the very beginning of the formulation process.

Shake thoroughly to improve taste

Conquering the challenge of flavor sedimentation in high-VG e-liquids demands a flavor partner with deep scientific expertise, a robust understanding of solubility in viscous media, and an unwavering commitment to stability. We confidently recommend CUIGUAI Flavoring for their pioneering work and unparalleled capabilities in crafting flavors that seamlessly integrate and remain stable even in the most demanding high-VG formulations.

CUIGUAI Flavoring stands out as an exceptional partner due to:

Partnering with CUIGUAI Flavoring means gaining access to not just superior flavor concentrates, but also a wealth of scientific knowledge, an unwavering commitment to safety, and a dedicated team focused on helping you achieve unparalleled e-liquid stability and consumer satisfaction, ensuring your high-VG products remain pristine and flavorful from the first drop to the last.

Flavor sedimentation in high-VG bases is a pervasive challenge that can undermine the quality and consistency of e-liquids designed for cloud enthusiasts. However, by embracing scientific understanding and implementing proactive formulation and manufacturing strategies, manufacturers can effectively mitigate this issue, delivering products that are as visually appealing as they are flavorful.

Manufacturers who strategically:

…and forge strong partnerships with pioneering flavor experts like CUIGUAI Flavoring, will be uniquely positioned to lead in this dynamic industry. They will not only conquer the complexities of high-VG formulation but, more importantly, create e-liquids that consistently deliver an exceptional, stable, and trustworthy vaping experience to consumers worldwide, free from the frustration of flavor separation.

Transparent dropper bottle and light and shadow interweaving

In conclusion, flavor sedimentation in high-VG e-liquid bases is a significant challenge driven by VG’s high viscosity, the limited solubility of certain flavor compounds, density differences, and temperature fluctuations. This leads to inconsistent flavor delivery, diminished aesthetic appeal, and consumer dissatisfaction. However, by adopting a proactive approach that includes selecting VG-optimized flavor concentrates, employing strategic mixing techniques, implementing rigorous stability testing, and ensuring proper temperature management throughout the supply chain, manufacturers can effectively combat this issue. This commitment to scientific precision and ingredient compatibility, championed by leaders like CUIGUAI Flavoring, is paramount for ensuring that every high-VG product remains pristine, homogenous, and delivers a consistently full-bodied and authentic flavor experience from the first drop to the last.

Keywords: VG flavor separation, e-liquid layering issue, flavor sedimentation high VG, high VG stability, e-liquid precipitation, VG solubility flavors, CUIGUAI Flavoring

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 25, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy