Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 31, 2026

Molecular Dance: Flavor Chemistry

The evolution of the e-liquid industry is a story of radical compression. In the early 2010s, the “open system” era dominated, characterized by large sub-ohm tanks and high-wattage devices. During this period, flavorists formulated concentrates intended for usage rates of 15%, 20%, or even 25%. These “traditional” concentrates were essentially diluted versions of aromatic compounds, where the carrier—typically Propylene Glycol (PG)—did most of the heavy lifting in terms of volume.

However, as we move through 2026, the market has pivoted. The rise of high-resistance pod systems, disposable devices, and a global push for manufacturing efficiency has birthed the era of Super-Concentrates (SC). These are systems engineered to deliver a full, complex sensory profile at a mere 1% to 2% usage rate.

But shifting from a 15% formulation to a 1% formulation is not as simple as removing 90% of the PG. It requires a fundamental restructuring of the flavor’s molecular architecture. It is a transition from “cooking” to “molecular engineering.” In this comprehensive technical guide, we will dissect the physics, chemistry, and industrial logistics behind formulating flavor systems that pack an entire sensory world into a single drop.

To understand how a flavor works at 1%, we must first understand the Odor Detection Threshold (ODT). The ODT is the lowest concentration of a certain chemical compound that can be perceived by the human olfactory sense.

Flavor compounds vary wildly in their potency. For instance, some esters might require several parts per million (ppm) to be detected, while certain sulfur-containing compounds or pyrazines can be detected by the human nose at parts per billion (ppb).

In traditional concentrates, flavorists often use “filler” aromatics—compounds with high ODTs—to build volume. In a Super-Concentrate, these fillers are purged. We focus exclusively on high-potency volatiles.

Technical Citation: Research in the Journal of Agricultural and Food Chemistry suggests that the formation of acetals in e-liquids can significantly alter the perceived flavor profile over time. Super-concentrates must be formulated with stabilizers or specific pH buffers to minimize these unintended chemical shifts during the “steeping” phase.

To achieve a 1% usage rate, the concentration of active volatiles in the bottle must be near-saturation. We quantify this using the Molar Concentration formula:

Where M is molarity, n is moles of solute, and V is volume of solution. In SCs, M is pushed to its physical limit before precipitation occurs.

The primary challenge of a 1% concentrate is solubility. You are attempting to fit a large mass of organic aromatic solids and oils into a very small volume of Propylene Glycol.

Flavorists use HSP to predict whether a flavor molecule will remain in a stable solution or “fall out” (recrystallize). HSP looks at three forces:

In a 1% super-concentrate, the density of flavor molecules is so high that the solution often nears its saturation point. If the temperature drops during shipping, the flavor components might crystallize. To prevent this, we utilize “co-solvents” like Triacetin or Ethanol in micro-doses to bridge the solubility gap, ensuring the concentrate remains a homogenous liquid from the factory to the end-consumer.

PG is the ideal carrier because of its low viscosity and its ability to act as a humectant. In a super-concentrate, the PG acts as a “molecular cage,” holding the volatiles in place. When the 1% concentrate is finally added to a base of Vegetable Glycerin (VG) and PG, the low-viscosity concentrate must disperse rapidly.

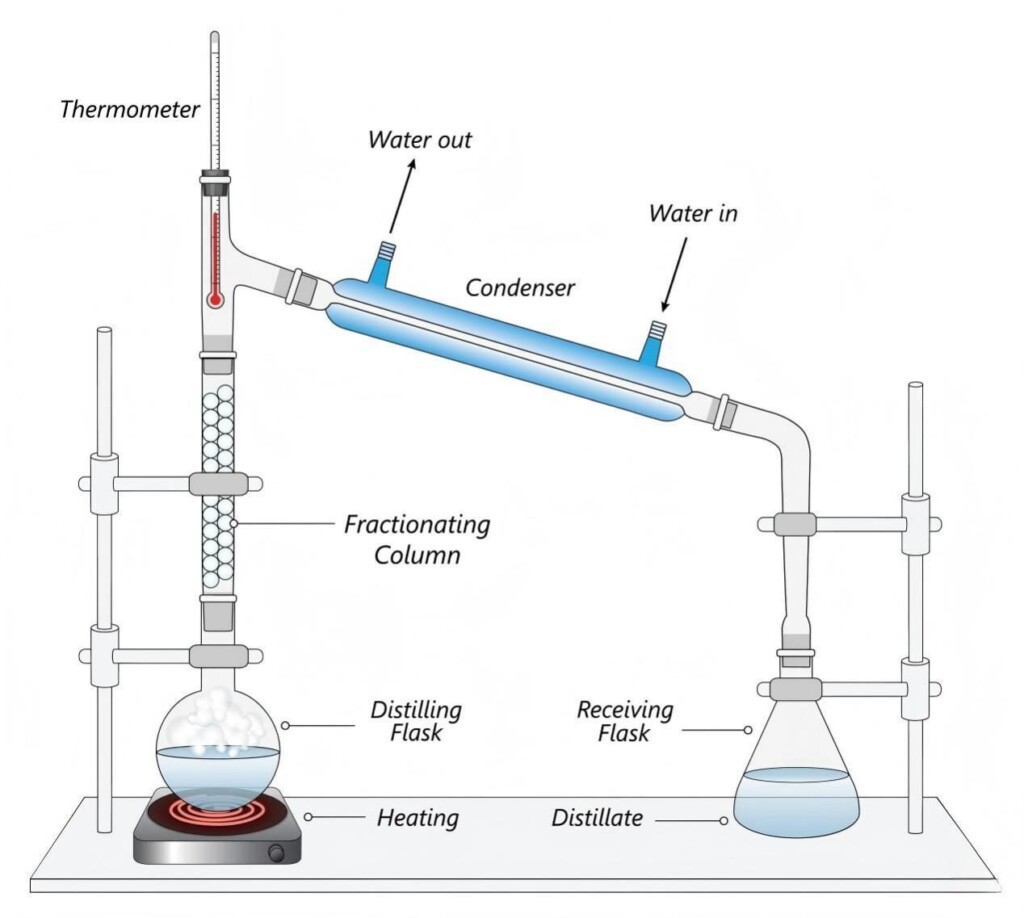

You cannot reach a 1% usage rate using standard food-grade extracts. Traditional cold-pressing or simple steam distillation leaves behind too many “heavy” non-volatile waxes and resins. These components do not contribute to flavor in vapor form; instead, they gunk up coils and dilute the aromatic strength.

We utilize Molecular Distillation, a process that operates under a high vacuum. This allows us to separate flavor fractions at temperatures far below their atmospheric boiling points. By doing this, we avoid thermal degradation—the “burnt” taste that occurs when delicate fruit molecules are overheated.

The result is a “Heart Cut” of the flavor:

Short-Path Distillation Diagram

For botanical profiles (like tobacco or vanilla), we employ supercritical CO2 extraction. By manipulating CO2 into a state where it acts as both a gas and a liquid, we can target specific flavor molecules without extracting the bitter tannins or heavy plant waxes that are common in traditional ethanol extracts.

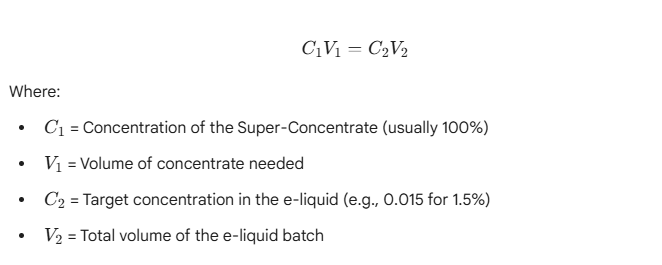

When working with a usage rate of 1.5%, the margin for error disappears. In a traditional 15% mix, if a technician is off by 0.5%, the final concentration is 14.5%—a negligible change. In a super-concentrate, if you are off by 0.5%, you have changed the flavor profile by 33%.

The standard dilution formula applies:

For a 1,000-liter industrial batch, a 1.5% usage rate requires exactly 15 liters of concentrate.

To maintain quality at these low rates, manufacturers must invest in Gravimetric Dosing Systems. Unlike volumetric pumps, which can be affected by the thermal expansion of liquids, gravimetric systems measure the weight of the ingredient to the tenth of a gram. This is the only way to ensure that a 1% formulation tastes the same in January as it does in July.

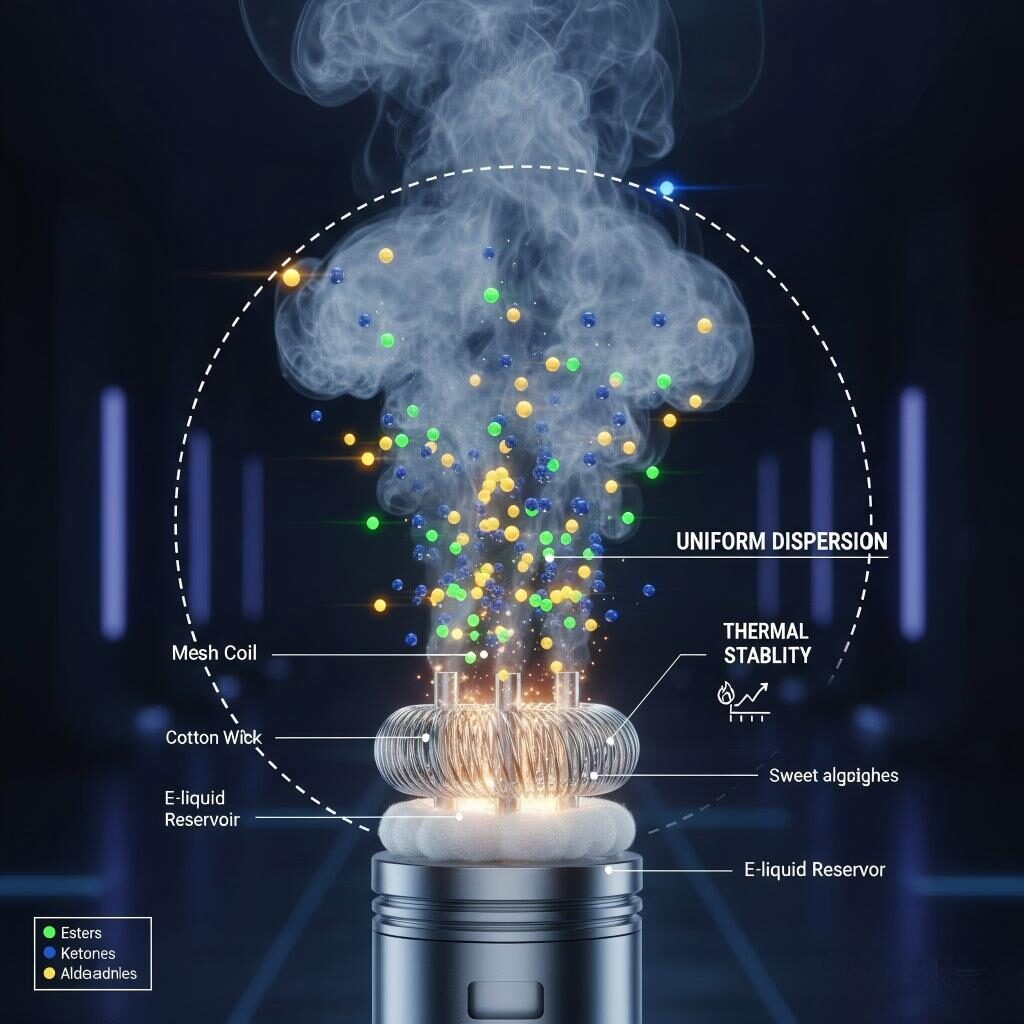

The ultimate test of a super-concentrate is the “Vaporization Event.” When the e-liquid hits the heating element (usually at temperatures between 180 ℃ and 240 ℃), the flavor molecules must transition from liquid to gas simultaneously with the carrier.

If the flavor volatiles have boiling points significantly lower than the PG/VG base, they will “flash off” instantly, leading to a harsh, concentrated burst of flavor on the first puff followed by a muted experience.

To solve this, SCs are formulated with fixatives. These are high-molecular-weight, flavorless compounds that “anchor” the lighter volatiles to the carrier. This ensures a linear evaporation rate. According to the American Chemical Society, the interaction between solutes and solvents in aerosol generation is a critical factor in “flavor consistency” across the lifespan of a heating coil.

Vape Coil Flavor Dynamics

The effectiveness of a 1% flavoring is also dependent on the droplet size of the aerosol. Smaller droplets (<1 μm) have a higher surface-area-to-volume ratio, allowing for more efficient delivery of flavor molecules to the olfactory receptors. Super-concentrates are engineered to promote fine atomization, which is why they perform so well in low-power pod devices.

A common complaint when switching to super-concentrates is Olfactory Fatigue, or “vaper’s tongue.” This occurs when the brain’s olfactory bulb becomes saturated and stops sending signals to the brain.

Counter-intuitively, adding more flavor concentrate often results in less perceived flavor. At high concentrations, the molecules compete for the same receptor sites in the nose. In a 1% formulation, the molecules are spaced appropriately, allowing the receptors to reset between puffs.

In SC formulation, we use “Synergy Pairs.” For example, adding a microscopic amount of Ethyl Maltol to a strawberry flavor doesn’t just add sweetness; it physically enhances the volatility of the strawberry esters, making them more perceptible at lower concentrations. Conversely, we use “Masking Agents” to suppress the peppery throat hit of high-concentration nicotine, allowing the 1% flavor profile to shine through.

In 2026, the regulatory burden on e-liquid manufacturers is immense. From the FDA’s PMTA in the United States to the TPD in the European Union, every milligram of an ingredient must be accounted for.

Super-concentrates make compliance easier. When you use less flavoring, you are introducing fewer total chemicals into the final product.

According to data from Mordor Intelligence, the global e-liquid market is projected to reach over $6 billion by 2030, with a significant shift toward high-compliance, transparently manufactured concentrates.

It is important to note that the Flavor and Extract Manufacturers Association (FEMA) designates flavors as “Generally Recognized as Safe” (GRAS) for ingestion. As the FEMA official website notes, this does not automatically cover inhalation. Therefore, our R&D process involves Inhalation Toxicology Screening to ensure that our concentrates do not produce harmful byproducts like formaldehyde or acrolein when heated.

While the per-liter price of a super-concentrate is higher than a traditional flavoring, the Effective Unit Cost is dramatically lower.

Consider a 1,000-unit production run of 10ml e-liquids:

Shipping 150ml of liquid via air freight is a fraction of the cost of shipping 1.5 liters. Furthermore, the storage requirements in your warehouse are reduced by 90%. In the context of “Just-In-Time” (JIT) manufacturing, SCs allow for much tighter inventory control and lower overhead costs.

If your facility is currently set up for 15% usage rates, switching to 1% requires a protocol change:

When e-liquid is mixed, it undergoes a process colloquially known as “steeping.” In scientific terms, this is a combination of homogenization and slow-burn chemical reactions.

Because super-concentrates are so dense, they do not naturally diffuse through a high-VG base quickly. We recommend the use of Ultrasonic Homogenizers. These devices use high-frequency sound waves to create cavitation bubbles that, upon collapsing, tear the flavor molecules apart and distribute them evenly throughout the liquid. This reduces steeping time from weeks to minutes.

Super-concentrates are highly susceptible to oxidization due to the high density of unsaturated esters. We package our SCs under an Argon Blanket—an inert gas that is heavier than air. This prevents oxygen from touching the liquid during storage, ensuring the flavor profile remains “fresh” for up to 24 months.

A major criticism of early low-dosage flavorings was that they felt “thin” or “watery.” In 2026, we solve this using Non-Flavor Modifiers.

By incorporating food-grade vegetable-derived gums or specific cellulose ethers that are stable under heat, we can replicate the “thick” mouthfeel of a 20% flavor concentrate while only using 1%. These modifiers do not add flavor but increase the viscosity of the vaporized aerosol, giving the sensation of a richer, more “creamy” vape.

Cooling agents like WS-23 or WS-3 are commonly used in SCs. However, because they are crystalline solids at room temperature, they must be pre-dissolved into the SC at precisely controlled temperatures to prevent “fall-out” in the final e-liquid.

The move to Super-Concentrates is an inevitable step in the maturation of the e-liquid industry. It represents a move away from the “home-brew” aesthetics of the past and toward a future of pharmaceutical-grade precision. By formulating at 1-2%, manufacturers gain total control over their product’s consistency, safety, and profitability.

Premium SC: 1% Flavor Concentrate

We invite you to experience the difference that molecular precision makes. Whether you are looking to optimize your current best-sellers or develop a new signature line, our technical team is ready to assist.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy