Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 20, 2026

E-Liquid Lab Quality Control

In the high-speed world of e-liquid manufacturing, consistency is currency. As a producer, your bottom line depends on the ability to fill thousands of bottles per hour with precise accuracy, minimal waste, and zero downtime. Yet, even with top-tier automated filling equipment, production managers often face baffling issues: variations in fill volumes, excessive dripping from nozzles, or pumps that seem to struggle mid-run.

Often, the culprit isn’t mechanical failure; it’s incorrect physics. It is a misunderstanding of Specific Gravity (SG).

As a specialized manufacturer of flavorings for the e-liquid industry, we understand that a great flavor profile is only half the battle. The finished product must also be machinable. Bridging the gap between the flavor chemist’s beaker and the production floor’s piston filler is crucial for scaling up successfully.

This technical guide will move beyond basic mixing ratios to explore the science of specific gravity, its profound impact on automated filling dynamics, and actionable strategies to align your formulations with your machinery for seamless production.

To master your filling process, you must first define the variables rigorously.

Specific Gravity (SG), also known as relative density, is a dimensionless quantity. It is the ratio of the density of a substance (in this case, e-liquid) to the density of a reference substance. For liquids, that reference is almost always pure water at its densest point (4°C), where it has a density of approximately 1.000 g/cm³.

Put simply:

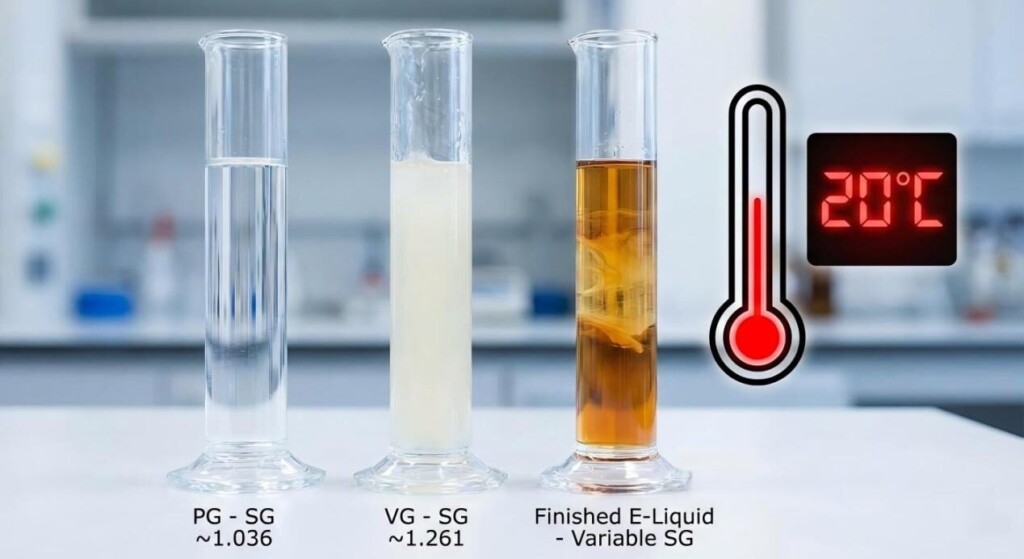

E-liquids are complex non-aqueous solutions. Their specific gravity is a weighted average of their components. The primary drivers of SG in any e-liquid formulation are Propylene Glycol (PG) and Vegetable Glycerin (VG), which have vastly different physical properties.

*(Source: The specific gravities of common chemical compounds like PG and VG are standard physical constants readily available in chemical engineering databases and safety data sheets provided by major suppliers such as Dow Chemical or via PubChem.)

Flavor concentrates, nicotine solutions (usually suspended in PG or VG), and sweeteners also contribute to the final SG, but the PG/VG ratio is the dominant variable. A “Max VG” e-liquid will always have a much higher specific gravity than a 50/50 blend.

It is impossible to discuss specific gravity without discussing temperature. Liquids expand when heated and contract when cooled. As volume changes while mass remains constant, density—and therefore specific gravity—shifts.

For e-liquids, particularly high-VG formulations, this relationship is significant. A shift of just 5°C to 10°C on the production floor (perhaps due to machinery heat or changing seasons) can measurably alter the SG of the liquid being fed into the filler. If your quality control (QC) lab measures SG at a controlled 20°C, but the production floor is running at 28°C, the liquid entering the nozzles is physically different from the liquid that was approved.

Why does a machine made of steel and pneumatic pistons care about the density of the liquid?

The fundamental issue lies in how most liquid filling machines operate: Volumetric Filling.

Whether you are using piston fillers, peristaltic pumps, or gear pumps, these machines are typically designed to displace a specific volume of liquid into the container during each cycle. They do not inherently measure weight.

However, regulatory compliance and product consistency are often determined by net weight, or at least a volume that accurately reflects the labeled quantity under specific conditions.

If your machine is calibrated to deliver exactly 30ml of liquid, it will deliver that 30ml volume regardless of what is in the hopper.

If you are filling by volume to hit a target weight, a higher SG liquid means you need to dispense less physical volume to achieve that weight. If you don’t adjust the machine, you will overfill every bottle by weight, giving away product and potentially causing overflow messes. Conversely, if you switch from a heavy liquid to a lighter one without adjusting, you will underfill.

It is vital to distinguish between Specific Gravity (density) and Viscosity (resistance to flow). While they are often correlated in e-liquids (high VG is both heavy and thick), they are distinct properties that challenge filling machines in different ways.

According to packaging industry resources, understanding the interplay between liquid characteristics and pump mechanics is the first step toward optimization. “The physical characteristics of the liquid—specifically viscosity, specific gravity, and particulate content—dictate the type of filling technology required and the operational parameters of that technology.” (Source: PMMI, The Association for Packaging and Processing Technologies, often discussed in their technical white papers on liquid filling).

Piston Filling Machine Nozzles

Before you can adjust for specific gravity, you must measure it accurately. Relying on theoretical calculations based on PG/VG ratios is insufficient for production due to the variable impact of flavorings and sweeteners.

A hydrometer is a sealed glass tube with a weighted bulb that floats in a cylinder of the liquid. The SG is read at the surface level where the liquid intersects the stem. While inexpensive, hydrometers can be difficult to read accurately with viscous, darker e-liquids because the meniscus (the curve of the liquid surface) can be obscured or distorted by the thick liquid clinging to the stem.

A pycnometer is a flask with a precisely known volume and a stopper containing a capillary tube. By weighing the flask empty, filled with water, and filled with the e-liquid (at the exact same temperature), you can calculate the SG gravimetrically. This is highly accurate but time-consuming and requires very precise analytical balances.

For modern e-liquid manufacturing, a digital density meter based on the oscillating U-tube principle is essential. The instrument introduces a sample into a glass U-tube and causes it to oscillate electronically. The frequency of oscillation changes depending on the mass (and thus density) of the liquid inside.

These devices offer several advantages:

(Source: Principles of oscillating U-tube density measurement are detailed in analytical chemistry textbooks and manufacturer documentation from leaders in instrumentation like Anton Paar or Mettler Toledo.)

As flavor manufacturers, we see firsthand how flavor choices impact the physical properties of the final e-liquid.

Flavor concentrates are almost universally carried in Propylene Glycol (PG). Sometimes ethanol or triacetin is used, but PG is the standard. This means that flavorings generally act as “thinning agents” and “density reducers” relative to VG.

If you have a base formulation of 70% VG / 30% PG, and you add 15% flavor concentrate (which is mostly PG), your final effective ratio shifts significantly toward PG.

This shift lowers both the viscosity and the specific gravity.

Conversely, “sweeteners” like sucralose or ethyl maltol are often dissolved in PG, but they add significant dissolved solids to the mixture, which can increase specific gravity even while the carrier liquid tries to lower viscosity.

The most challenging formulations for automatic fillers are usually high-VG, high-sweetener dessert flavors. These combine high viscosity (resistance to flow) with high specific gravity (heavy mass and inertia). This combination puts maximum strain on pump seals and demands precise nozzle control to prevent dripping.

PG vs VG Specific Gravity Chart

When your filling machine struggles, you have two avenues for correction: adjust the machine (discussed in section 6) or adjust the liquid. As formulation chemists working with production teams, we favor a proactive approach where machinability is considered during the R&D phase.

If a high-VG product is causing excessive pump wear or inconsistent fills due to cavitation (the pump pulling a vacuum because the liquid won’t flow fast enough), the simplest formulation fix is increasing the PG content.

Even a shift from 80/20 VG/PG to 75/25 VG/PG can significantly improve flow characteristics without substantially altering the consumer’s vape experience (cloud production/throat hit). This slight reduction in SG and viscosity allows the piston to draw the liquid more smoothly.

Don’t use a “pre-mixed” base of 70/30 VG/PG and then add flavors. This guarantees batch inconsistency because different flavor profiles require different percentages of concentrate. A 5% fruit flavor load will result in a thicker, heavier final product than a 20% complex dessert flavor load, even if they both started with the same base.

Formulations should be calculated from raw component percentages to achieve a consistent final ratio. If you aim for a final 70/30 ratio, and your flavor percentage is 15%, your initial mixing base needs to be higher than 70% VG to compensate for the incoming PG-based flavor.

While not a formulation change per se, manipulating temperature is a powerful process aid. If you cannot alter the VG/PG ratio due to product requirements, you can temporarily reduce the liquid’s specific gravity and viscosity by heating it during the filling process.

Using heated hoppers or inline heat exchangers to raise the e-liquid temperature to 30°C–40°C can dramatically improve machinability. The liquid becomes thinner and slightly less dense, flowing into pistons more easily and breaking cleanly from nozzles.

Caution: Excessive heat can degrade nicotine and certain delicate flavor aromatics. Heating should be strictly controlled and validated by your flavor supplier.

Sometimes, the formulation is set in stone. In these cases, the machine must bend to the physics of the liquid. When dealing with high specific gravity e-liquids, the following adjustments on piston filling machines are critical.

A heavy, viscous liquid cannot be rushed. If the piston retracts too quickly on the draw stroke, it will create cavitation—voids in the liquid—resulting in underfills. If it dispenses too fast, the high pressure can cause splashing in the bottle.

High SG liquids require slower, deliberate pump cycle speeds. This may reduce units per minute (UPM), but it increases usable units.

This is the most critical setting for preventing drips with high-SG liquids. Because a heavy liquid has high inertia in the nozzle, it wants to keep falling even after the piston stops pushing.

The “suck-back” feature briefly reverses the piston at the very end of the dispense cycle, pulling a small amount of liquid back into the nozzle tip. This breaks the surface tension and prevents that final heavy drop from falling onto the conveyor. The higher the SG and viscosity, the more aggressive the suck-back setting typically needs to be.

Using a small diameter nozzle for a high-SG, thick liquid increases backpressure on the pump. Conversely, a nozzle that is too wide may not provide enough surface tension to hold the heavy liquid in between cycles, leading to dripping regardless of suck-back settings. Selecting the correct nozzle size relative to the liquid’s physical properties is essential for a clean cutoff.

(Source: Technical guides on filling machinery operation often emphasize the relationship between product characteristics and nozzle selection to ensure clean product cutoff. See resources from organizations like the Institute of Packaging Professionals – IoPP).

Specific Gravity is more than just a number on a spec sheet; it is a fundamental physical property that dictates how your product interacts with your machinery.

Ignoring SG leads to a constant battle on the production floor—fighting drips, chasing weight variances, and replacing worn pump seals. By understanding the science determining specific gravity in e-liquids and implementing precise measurement protocols, you can proactively adjust formulations for better machinability.

When formulation changes aren’t possible, understanding the physics of heavy liquids allows you to calibrate your automatic fillers—adjusting speeds, pressures, and drawback settings—to handle high-VG products efficiently.

The goal is a harmonious balance where the chemistry of the e-liquid complements the mechanics of the filler.

As a manufacturer of specialized flavorings, we don’t just supply tastes; we supply solutions. We understand that our flavors must perform in your tanks and machines as well as they do in a vape device.

If you are struggling with production inconsistencies related to specific gravity, viscosity, or flavor interaction, our technical team is ready to assist. We can help analyze your current formulations and suggest adjustments to improve flow characteristics without compromising the flavor profile your customers love.

Efficient E-Liquid Production Line

Are production bottlenecks costing you money? Let’s optimize your process.

Contact our technical support team today to discuss your specific challenges with e-liquid filling. We offer consultation on formulation adjustments and can provide flavor samples designed to perform on high-speed automated lines.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy